PCB PCBA Solutions!

Global Industries.

PCB PCBA Solutions!

Projects

Employees

Ready to Bring Bigger, Better, Faster & Stronger Projects Than Ever!!

We provide one station service from PCB, PCBA, china PCB assembly, molds, plastic injection, CNC enclosure, metal parts , Wireless charger ODM,wireless battery charger to final product assembly in china! – PCB Assembly in china ,PCBA board manufacturer

Best A Grade Electronic

Manufcturering Services

Since1998, 25 Year professional Electronics Manufacturing Service (OEM/ODM) partner!One station service from PCBA, PCB assembly, molds, plastic injection, CNC enclosure, metal parts,wireless charger ODM to final product assembly.

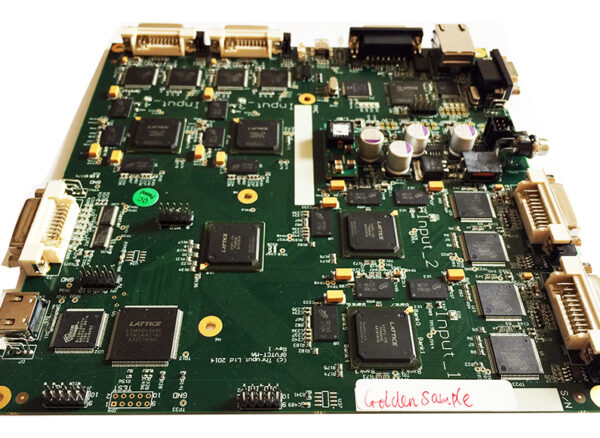

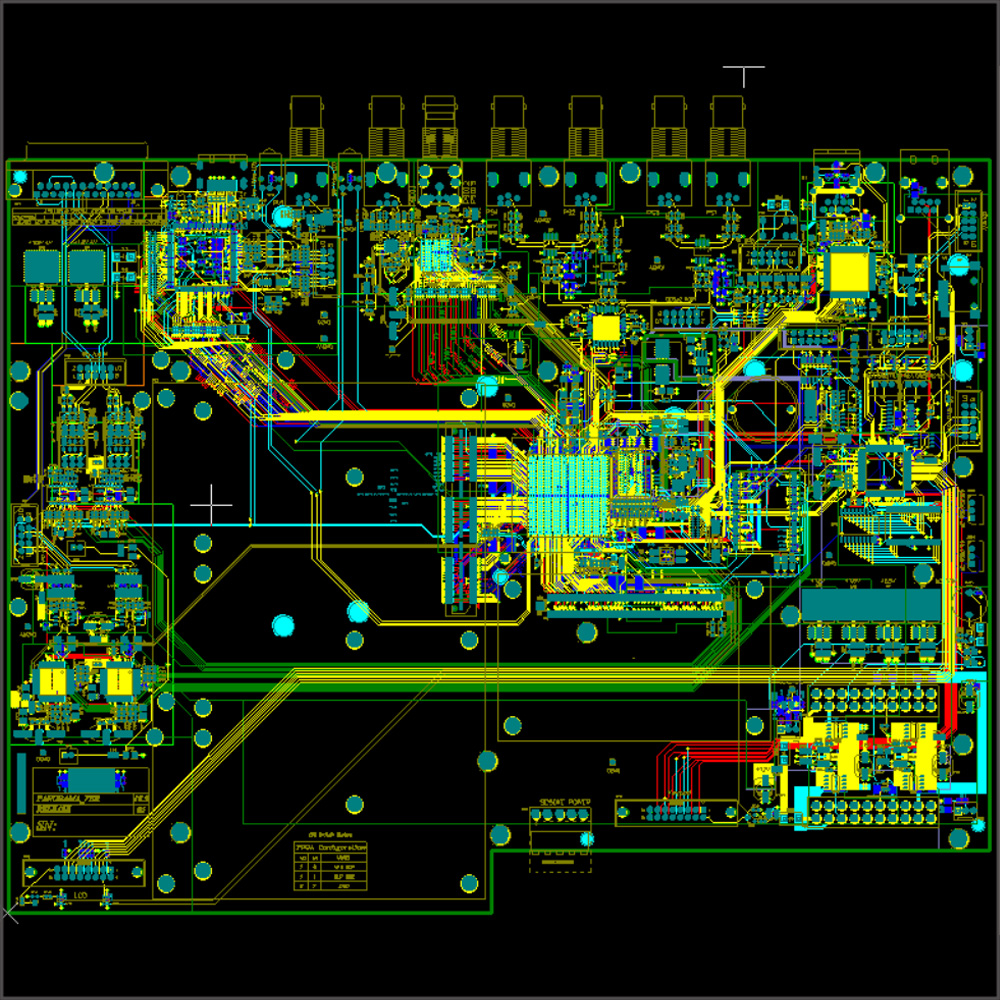

PCB layout & Sch Design

- Consume Electronics

- Computer Electronics

- industrial Electronics

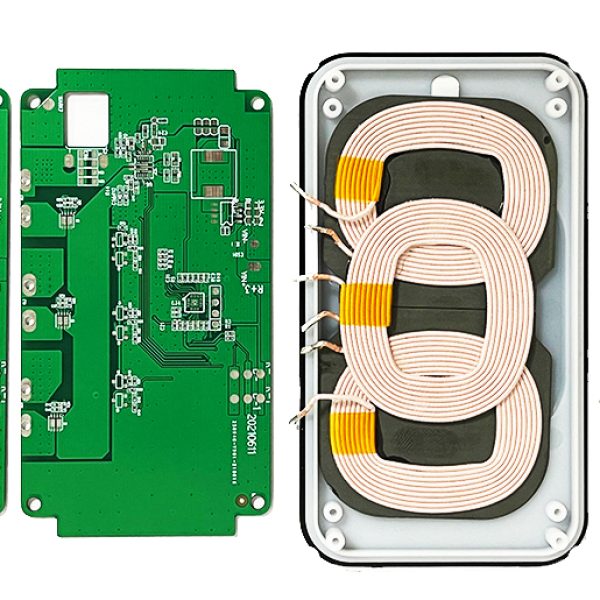

Wireless charger ODM

- Project manager

- Contract administrator

- Consulting engineer

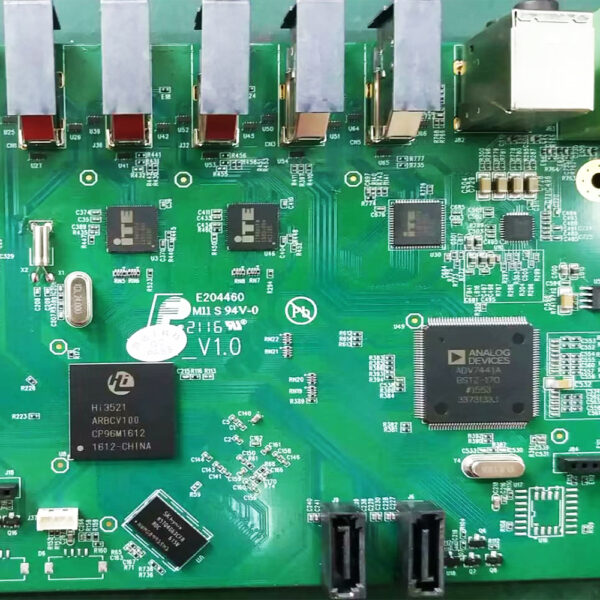

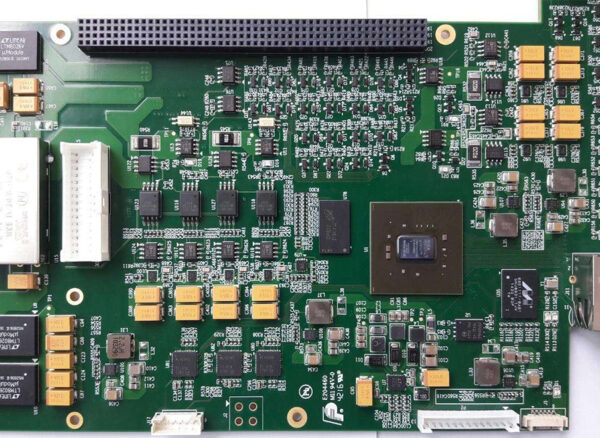

Mutil-layer PCB board

- Own PCB Factory

- Planning and scheduling

- Over 20 Years engineer

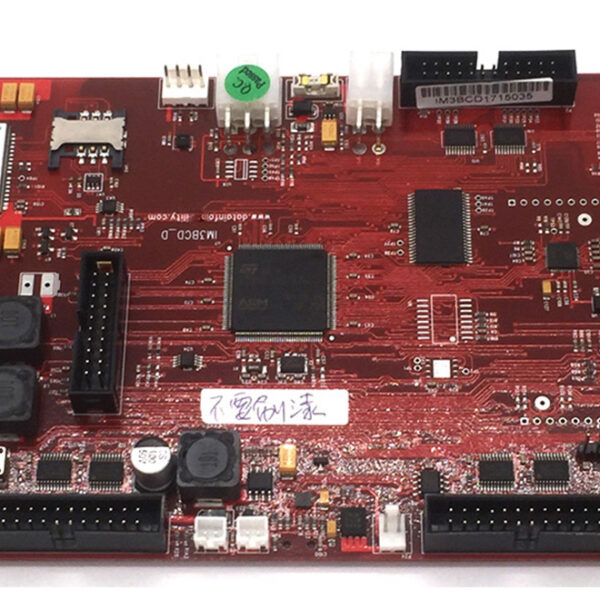

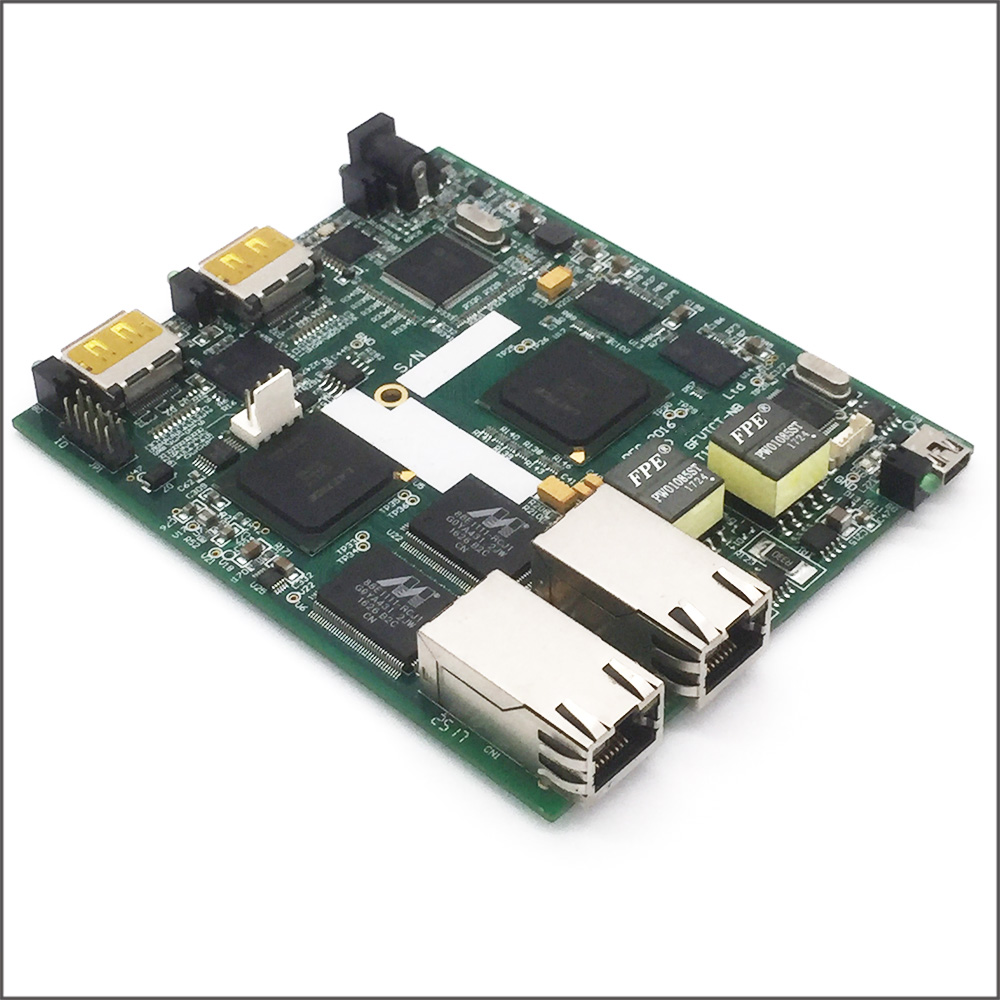

Electronic PCB & PCBA

- Project manager

- Contract administrator

- 10 SMT Production line

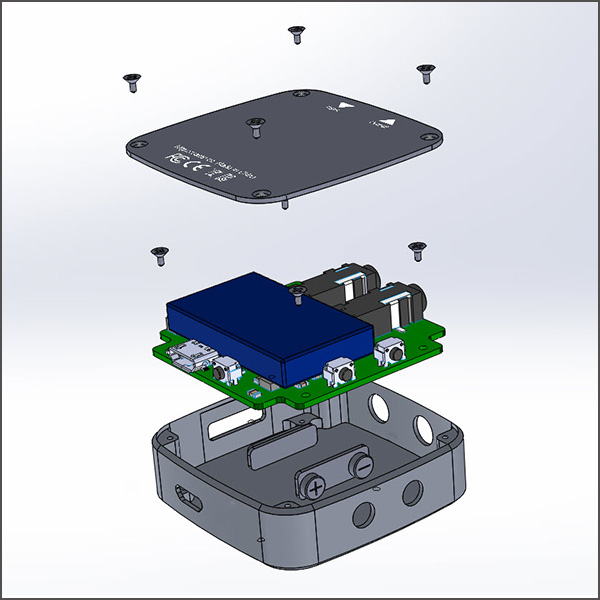

FinalProduct Assembly

- Owm PCB Production

- PCBA Contract manufacturer

- 8 Final Assembly line

Elec Product OEM & ODM

- ID, Mechanic design

- Electronic solution design

- Final product assembly

Pushing The Boundaries Of What’s Possible.

Evaluation Quotation by Gerber file & BOM

PCB PCBA prototype and approval

Implementation Of mass production Quality Works.

Featured Projects

Wireless Charger PCBA

Communications industry

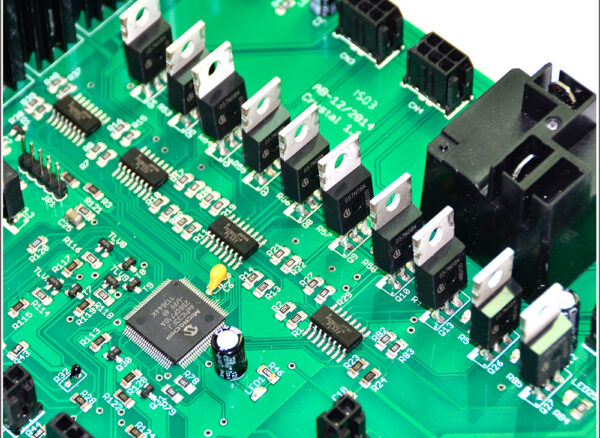

Industrial Automation

Security monitoring

Bus station Display

Medical beauty industry

We Help Build On Past & Prepare For Your Future.

Control System

High security requirements and are certified to highest local.

Workmanship

Take great pride in everything that we do in our Company.

100% Satisfaction

Building projects impressive list of long-term clients.

High Performance

Recognized as one of World's leading Construction firms.

Professional Staff

Involves of unknown risks and challenging regulations.

Unique Solutions

Bring bigger, better, faster and stronger projects than ever.

Martin Hope

Mike Dooley

Request A Quote

We take great pride in everything that we do, complete control over products allows us to ensure our customers receive the best quality service.

Committed To Delivering High Quality Electronic Projects And Innovate Design!

Projects & Residentials Completed in 2022

Qualified Employees & Workers With Us

Satisfied Clients We Served Globally

Years Of Experience In The Industry

Providing Full Range Services And Solutions Worldwide.

Recent Articles

- 2023年9月14日

- Industry

Golden Weald BGA PCB Capacities-BGA FPGA PCB PCBA assembly manufacturer

- 2023年8月30日

- Industry

China wireless charger Power bank factory, wireless battery charger OEM manufacturer

- 2023年2月3日

- Industry

Golden Weald HDI PCB Capacities-HDI PCB assembly PCBA manufacturer

- 2022年11月11日

- Industry

China wireless charger PCBA factory, wireless charger OEM manufacturer

- 2022年10月19日

- Industry

Why Choose PCB Assembly In China-Since1998,GoldenWeald

- 2022年9月5日

- About SMT Technology

SMT (Surface Mount Technology) Manufacturing Process

Our Location

Add:1-4F, 2 build, YiJia Industrial Area, 6 YiJia Road, LongHua , ShenZhen, GuangDong, China

Quick Contact

Email:

Gamin_Wjj@goldenweald.com

Support: info@goldenweald.com

Opening Hours

From Monday – Friday

9:00 am to 24:00 pm